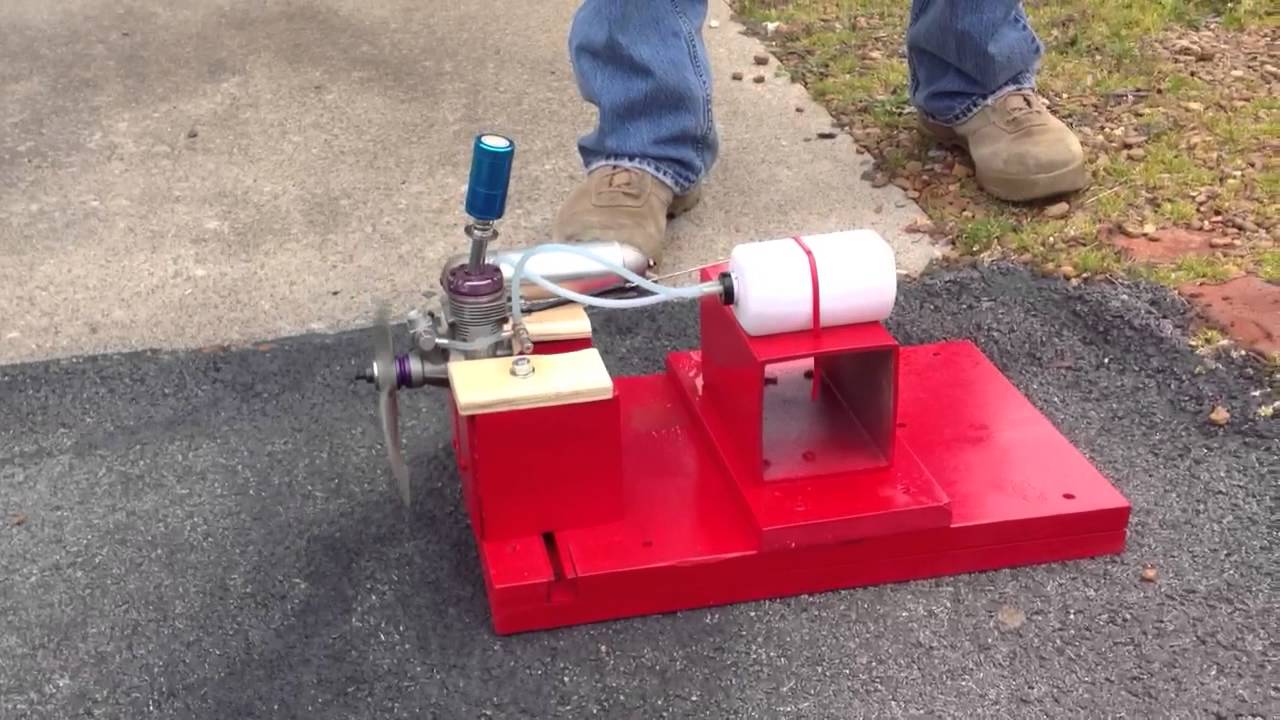

Decided i wanted to try and build my own test stand so.did a.little.research and came up with my own design.. For this reason, i decided to build an engine test stand to operate the engine prior to installation, plus, it is a good way to keep an engine from sitting too long without it being run. here are a few pictures of the almost completed engine test stand.. Engine stand project . i decided that it would be nice to have an engine run-in stand. place to bolt a motor, then fire it up and run it for break-in, tuning, and to find and fix any problems, such as leaks, before doing the final motor installation..

These are "blue-print type" plans to build our engine test stands. if you're handy in the shop, and can fabricate you can use these plans to construct the very engine stand we sell. this set of plans includes only a pdf file with blue print type plans.. Engine break-in stands have been around a long time, but what works for a relatively light-weight engine, such as a 550-pound small-block chevrolet, might be marginal for a pontiac that often tips. While not all engine stands are created equal, they do all share the majority of their dimensions and features. after all, they all do the same job, hold essentially the same engines dictating that they all be approximately the same size and shape, have the same brackets, attachments and basic features..